Mixing and Compacting

Mixing and Compacting are crucial steps in the powder metallurgy process, directly impacting the precision of product formation and stability of performance. This process mainly involves the following aspects:

01/

Powder Mixing Ratio

Different raw material powders are mixed according to predetermined formulation ratios to ensure uniformity in the powder composition, thereby enhancing consistency in forming and product stability.

02/

Compacting Techniques

The mixed powders are filled into molds and shaped through techniques such as pressing and injection molding, forming the initial shape of the product. This process requires selecting suitable forming techniques based on the specific requirements and shape characteristics of the product, along with corresponding process optimization and control to ensure product precision and surface smoothness.

03/

Sintering Process

The formed powder components are subjected to sintering in a high-temperature environment, inducing metallurgical reactions between powder particles to solidify and shape the material. Sintering temperature and time need precise control based on raw material properties and product requirements to ensure product density and mechanical performance.

04/

Post-processing Steps

After sintering, subsequent processing steps such as surface treatment and heat treatment are necessary to further enhance product surface smoothness and mechanical performance. Additionally, product inspection and testing are conducted to ensure compliance with customer usage requirements and standards.

Through precise control and optimization of the above processing steps, we can produce powder metallurgy products of excellent quality and stable performance, meeting various customer needs and application scenarios.

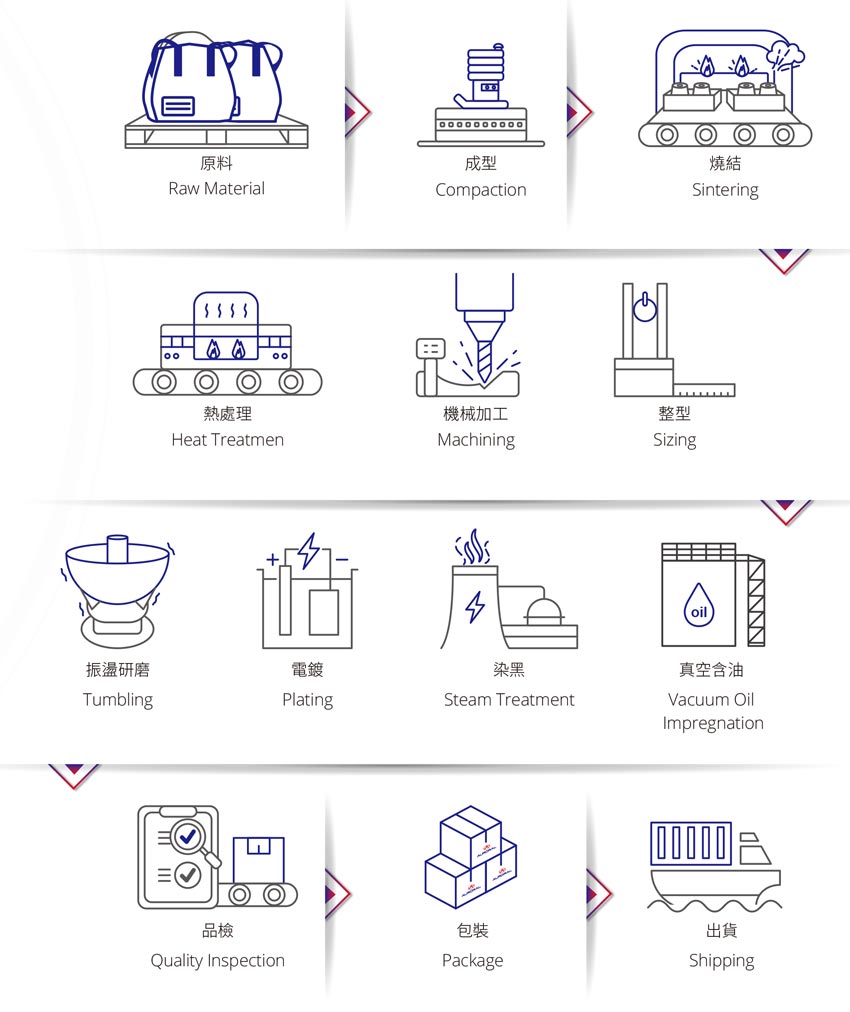

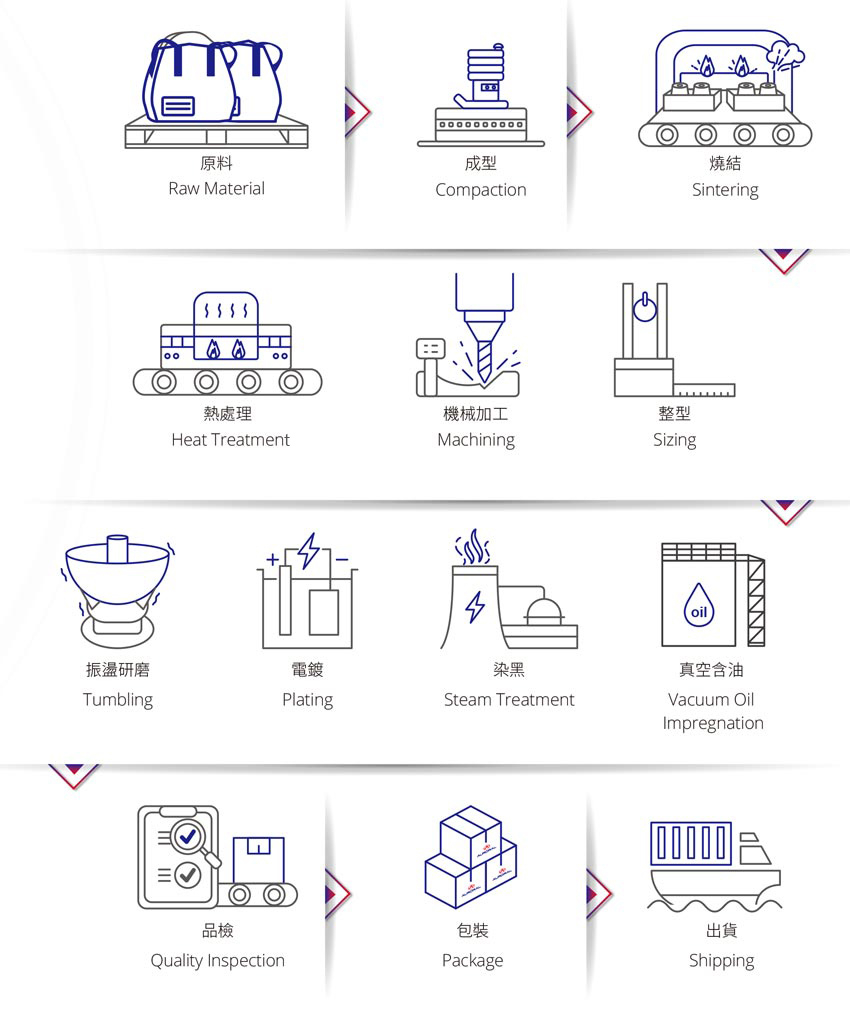

Flow Chart

Thank you for exploring our OEM/ODM solutions.

We prioritize exceptional technical support and will promptly address your inquiries.